Professional polystyrene foam cutting machine - manufacturers' review

The construction and manufacturing industries are placing ever higher demands on the precision and efficiency of processing insulation materials. A professional polystyrene cutting machine must be able to cope with intensive work in harsh factory conditions. What features distinguish industrial equipment from standard workshop models? Meet the key manufacturers and learn what to look for when choosing machines for large enterprises.

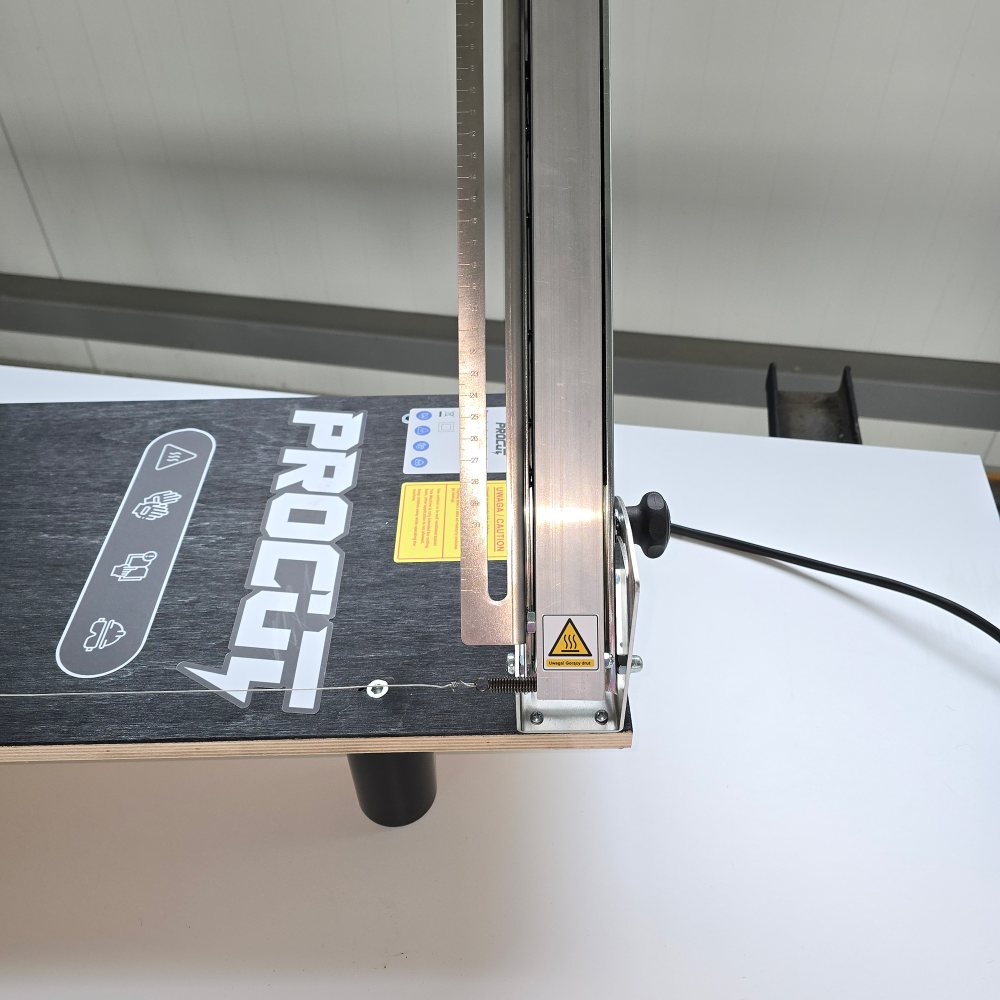

Characteristics of professional polystyrene foam cutting machine

Professional polystyrene foam cutting machine designed for industrial applications is distinguished primarily by its reinforced design and ability to work continuously for long hours.

Styrofoam cutters offered by our store represent different performance categories - from workshop equipment to industrial machinery. The key difference is the stability of operation at maximum loads and resistance to intensive use.

Industrial machines are characterized by larger work table dimensions, allowing standard-size plates to be processed without splitting them. Material guiding systems are more advanced and allow precise positioning of even very large parts. More powerful motors and power supplies ensure stable operation regardless of the thickness and hardness of the material being cut.

Market leader - Minova machines for industrial applications

Minova Pro 260W cutting machine is one of the best machines in the professional equipment category. The powerful 260W air-cooled power supply ensures continuous operation without overheating or power drops. The welded aluminum frame guarantees stability and precision even in the toughest industrial applications.

Minova machines stand out in the market thanks to their advanced technology and high quality workmanship. The 18mm thick waterproof laminated work surface is durable, yet easy to clean and maintain.The tool-free wire tensioning system allows for quick adjustment and replacement, which is crucial for intensive industrial work.

The universal mounting system allows for easy installation on scaffolding, making these machines ideal for companies performing construction work on various structures. An extensive kit in a carrying case includes everything you need to get started - a carrying bag, spare wires, a stand and handles.

Technical parameters of industrial machinery

Industrial machines are characterized by parameters adapted to the requirements of large-scale production.

The warm-up time to operating temperature is only 3-5 seconds, which significantly speeds up the start of work after a break. The power of the power supplies typically exceeds 200 watts, ensuring stable cutting performance even with difficult materials.

The milled, durable tape measures provide precision cutting for years of heavy use. Unlike stick-on scales, the milled markings will not rub off or peel off during use. The 8-cut system gives full versatility - from straight to groove cuts, eliminating the need for additional tools.

Manufacturer of hot polystyrene foam cutting machines

About the company Pro-Cut can be said to combine two approaches to the polystyrene cutting machine market.

We are both a manufacturer of Polish Procut machines and an official distributor of the renowned Minova brand, which allows us to offer customers a wide range of solutions - from budget models of our own production to advanced industrial systems.

As a manufacturer of Procut machines, we rely on years of experience in the construction industry and excellent knowledge of the needs of end users. Our machines are designed with real working conditions and the requirements of the Polish market in mind.

At the same time, the distribution of Minova machines allows us to offer top-level technologies for the most demanding applications.

Selection criteria for industrial polystyrene cutting machines

The selection of an industrial machine for cutting polystyrene foam requires consideration of many factors beyond the basic technical parameters.

Guide provides detailed guidelines for selecting equipment for specific applications. Planning the intensity of work, the types of materials to be processed, and determining the requirements for precision and repeatability of cuts are crucial.

Availability of technical service and spare parts is also an important aspect. In the case of industrial machinery, any downtime means loss of production, so quick service response is crucial.

Operating costs, including energy consumption and consumables, should also be considered.

The main criteria for selecting industrial machinery include:

- Power and stability of the power supply adapted to the planned load

- Work table dimensions suitable for standard boards

- Security and automation systems to enhance workplace safety

- Availability of service and spare parts in the country

- Expandable with additional features and accessories

Automation systems in polystyrene foam cutting machines

Modern industrial machines are increasingly equipped with automation elements to facilitate the operator's work and increase the precision of cuts.

Accessories such as high-quality resistance wires and advanced power supplies form the basis for automated systems. Automatic wire voltage regulation compensates for wire elongation during heating.

The automation systems also include programmable temperature controllers that allow optimal settings to be saved for different materials. With such a solution, the operator can quickly switch between saved profiles, greatly speeding up work in the production of a variety of parts. Advanced machines also offer automatic material positioning and repetition of programmed cutting sequences.

FAQ - Frequently asked questions about industrial machines for cutting polystyrene foam

What is the best polystyrene foam cutting machine for industry?

For industry, the best is the Minova Pro 260W with air cooling, a welded aluminum frame and a system of 8 types of cutting.

How much does a professional styrofoam cutting machine cost?

Prices of industrial machinery vary widely depending on the parameters - you will find exact prices in our offer or after contacting an advisor.

How much does it cost to rent a styrofoam cutter?

We do not offer rental services - we focus on selling high-quality machines with full service support.

What is the best styrofoam cutter for a construction company?

For construction companies, we recommend Minova Pro with a universal mounting system that allows installation on scaffolding.

What is the best for cutting Styrofoam in large quantities?

For large quantities, a machine with a powerful 260W power supply, air cooling and a tool-free wire changing system is best.