What is a thermal knife and how does it work?

Are you looking for a tool that will ensure precise cutting of polystyrene foam without fraying or crumbs? The thermal cutter is a solution that is revolutionizing the way you work with foam materials. Find out how this device works, what components it consists of and why professionals value it for its versatility of use!

What is a thermal cutter? A revolution in precision cutting of foam materials

A thermal knife is an electric hand tool that uses a heated blade to melt and precisely cut foam materials. Unlike traditional mechanical methods, where a saw or knife tears apart the structure of the material, the thermal knife melts it in a controlled manner along the cut line. This produces a smooth, closed edge without the characteristic crumbs or jaggedness.

This tool has gained popularity both in professional workshops and among hobbyists. Its mobility, ease of use and versatility of applications make it suitable for construction, advertising, modeling and artistic work.

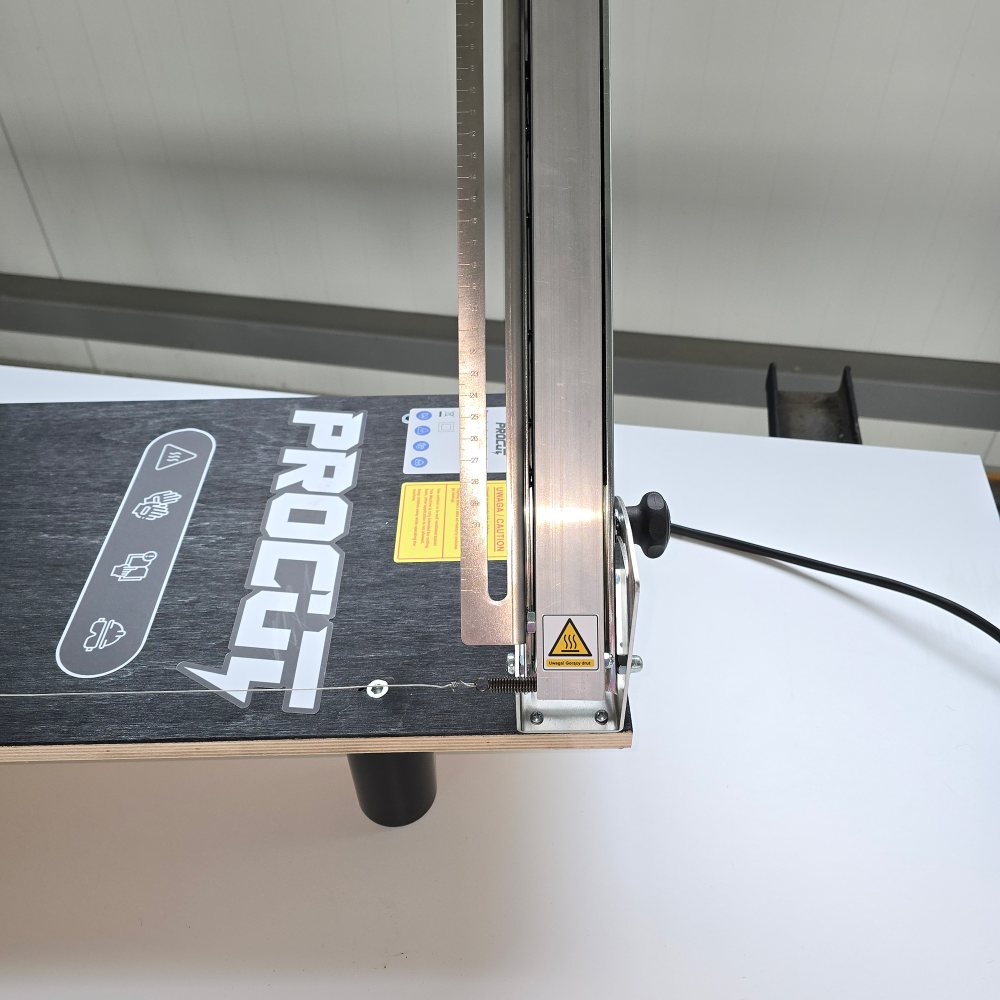

On offer Pro-Cut You'll find models to suit a variety of requirements - from basic household work to intensive professional use.

Advantages of the thermal knife

The main advantage of the thermal cutter is the quality of the achieved edge. The smooth, glossy surface does not require any additional finishing or grinding, which significantly speeds up work. The absence of dust and crumbs keeps the workstation clean, and the risk of inhaling fine material particles is minimal.

Key benefits of using a thermal knife:

- Cutting precision - ability to make complex shapes and details

- Clean work - No dust or waste characteristic of mechanical methods

- Mobility - compact design allows you to work anywhere

- Versatility - one set of blades handles different types of materials

- Saving time - no need for edge finishing

An additional advantage is the low barrier to entry. Operation of the thermal cutter does not require specialized training - after a few attempts, anyone will master the basic technique of guiding the tool, which allows you to achieve professional results.

How does the thermal cutter work? Construction of the polystyrene knife

The design of the thermal cutter is based on a simple but effective principle. The power supply converts the current from the outlet into the appropriate electrical parameters, which are fed to the heating element. This one heats up to 300-500°C in a few seconds. A heated blade mounted on the working tip melts the material as the tool moves along the intended cutting line.

Professional thermal knives consist of several key components. An ergonomic handle with thermal insulation ensures safe and comfortable operation even during prolonged use. A cooling system - usually active, with a fan - dissipates heat from electronic components, preventing overheating. The temperature control allows you to adjust the power to the type of material being cut.

How to cut Styrofoam with a thermal knife?

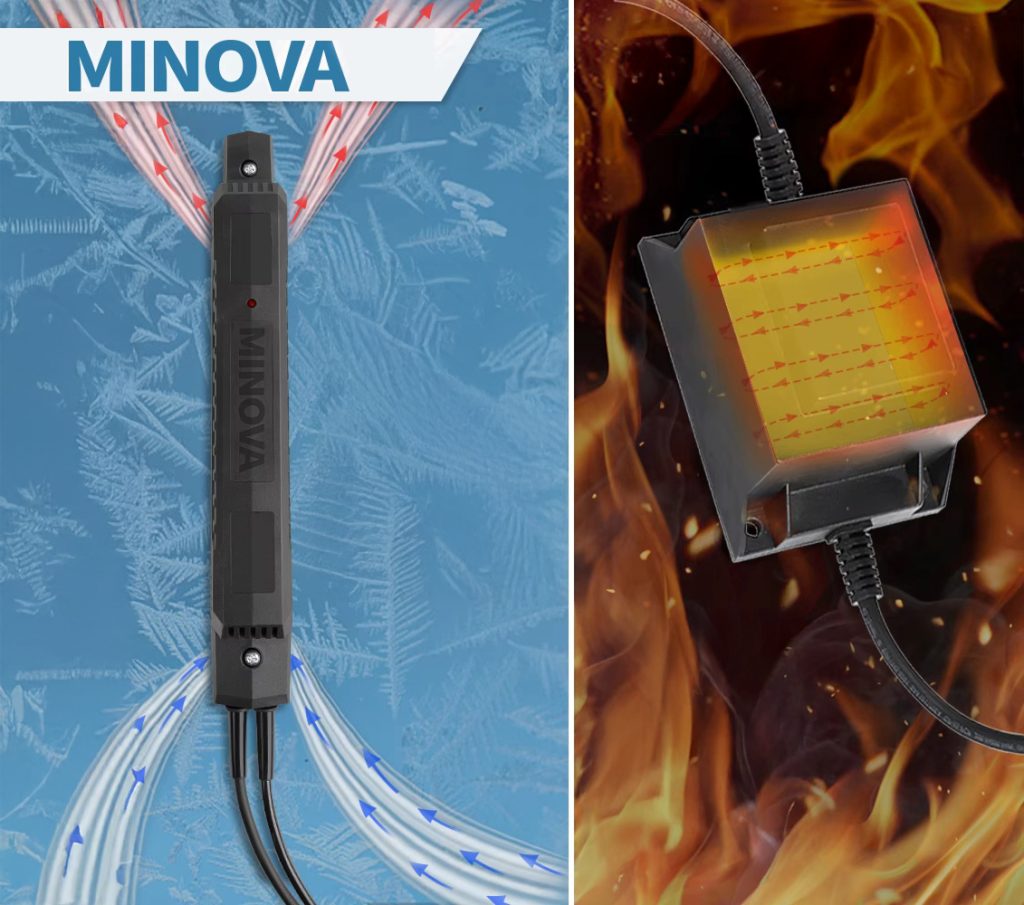

Proper cutting technique begins with proper preparation of the workstation. The material should be stably placed on a flat surface with the ability to move the knife freely. A model such as Minova 250W knife offered by Pro-Cut should be held securely, but without excessive pressure - the heated blade itself passes through the material under the influence of a small force.

The key to success is an even guiding speed. Moving too fast does not give the blade time to properly melt the material, resulting in rough edges. On the other hand, guiding too slowly results in excessive melting and dabbing. The optimal speed is about 5-10 cm per second, although the final value depends on the thickness and density of the material.

Electric Styrofoam cutter - how does it turn electricity into precision cutting?

The process of converting electricity into heat is based on Joule effect. The heating element, made of an alloy with high electrical resistance, heats up as the current flows. The higher the resistance of the conductor and the higher the power supply, the faster the heating and the higher the operating temperature. Modern power supplies use electronic power regulation, which allows precise temperature setting.

Key parameters of the electric cutter:

- Power supply power - determines the maximum temperature and heating rate

- Operating voltage - 230V standard for network models

- Warm-up time - 3 to 15 seconds depending on the model

- Temperature range - professional models reach 400-500°C

- Power adjustment - From a simple switch to a smooth adjustment

Stability of electrical parameters is a key factor affecting the quality of cutting. Cheap models often have problems with maintaining a constant temperature during operation - the blade heats up excessively during standstill and cools sharply during cutting, which negatively affects the uniformity of material melting.

Applications: from shaping to carving - the versatility of the thermal cutter

The thermal cutter is used in many industries and fields. In the construction industry, it is used to precisely fit insulation boards, cut holes for installations and bevel edges. The advertising industry appreciates it for its ability to create 3D letters and logos with an excellent quality finish. Learn about the various techniques cutting, molding and decorating, which open up new creative possibilities.

Modelers and artists use thermal knives to create mock-ups, dioramas and sculptures. Interchangeable blades of different shapes allow them to make both simple cuts and intricate details. Hook blades work well for cutting grooves and recesses, wavy blades create decorative edges, and thin pin blades allow precise engraving and drawing in the material.

Thermal knives for polystyrene foam - ranking of models by application

The choice of the appropriate model depends on the nature of the planned work. For occasional domestic use, basic models of 100-150W with simple temperature control will suffice. They offer sufficient performance for cutting thin Styrofoam panels and making simple shapes, although they may have limitations with thicker materials.

Professionals choose 200-250W models with active cooling and advanced temperature control. Such devices maintain stable parameters for long hours of work and cope with materials of different densities without losing cutting quality. A rotating head and a rich set of interchangeable blades increase versatility, allowing the most demanding projects.

FAQ - Frequently asked questions about the thermal cutter

What is the best styrofoam knife for a hobbyist?

For a hobbyist, a 150-200W model with basic temperature control and a set of several blades will be the best, providing sufficient capabilities at an affordable price.

What kind of styrofoam thermal cutter for cutting advertising letters?

For advertising letters, a 250W model with a rotating head, precise temperature control and a set of blades in various shapes for details and contours is ideal.

What is the best way to cut Styrofoam - with a 20 cm or 30 cm knife?

A blade length of 20 cm is sufficient for most applications and provides better control, while 30 cm is useful for thicker plates, but requires more experience.

Which Styrofoam cutter has the fastest heat-up time?

The fastest warm-up time of 3-5 seconds is offered by professional 250W models with advanced power supplies, basic models need 10-15 seconds.