Blade thermal knife - when is it a better choice?

Wire or blade? This is a question that is asked almost every time you buy Styrofoam cutting equipment. While wire cutters dominate for straight cuts, a thermal knife with a blade opens up completely different possibilities. Grooves, bevels, complex spatial shapes - these are tasks where the blade is no match! Discover when it is worth reaching for a blade knife instead of a traditional wire, and how to use its full potential in practice.

Wire or blade - which to choose?

The choice between wire and blade depends on the nature of the work to be done. A wire is ideal for long, straight cuts - it cuts through the material across the width in one motion. A blade gives precision and control for work that requires curves, details or cuts at different angles. It is a mobile tool that allows you to work directly on site.

The key difference is in the method of guidance. The wire requires stable support and guidance along a set line. The blade is guided like a regular knife - by hand, with full freedom of movement. This flexibility makes the blade knife indispensable for finishing, fitting and artistic work.

W Pro-Cut We understand these needs and offer customized solutions for a variety of applications.

How is a knife with a flat blade constructed?

The design of the thermal knife is based on a simple principle - a heating element heats the metal blade to a temperature of 300-500°C. Thermal knives consist of an ergonomic handle with thermal insulation, a heating system powered by a wire or battery, and a replaceable blade mounted on the working tip. A cooling system, usually active with a fan, dissipates heat from the electronics and the handle.

The manufacturing quality of the blade is crucial. Professional blades are made of stainless steel or heat-resistant alloys. The surface must be smooth, without bumps - any scratch or burr leaves a mark on the material. The thickness of the blade also matters - thinner ones give more precise cuts, thicker ones are more mechanically durable.

Types of blades you will meet in the store

Various blade shapes are available to suit specific tasks. The straight blade is the basic option for linear cuts and general-purpose applications. The hook blade is great for cutting grooves and recesses - the curved shape guides the tool along lines without slipping. The wavy blade creates decorative edges, and the thin pin blade allows for engraving and drawing in the material.

Blade types by application:

- Straight flat - universal cuts, beveling edges

- Hooked curved - grooves, recesses, guided cuts

- Wavy ornamental - decorative finishes, artistic effects

- Pin thin - fine detailing, engraving, drawing

- Wide solid - thick materials, intensive work

When is it better to reach for a blade instead of a wire?

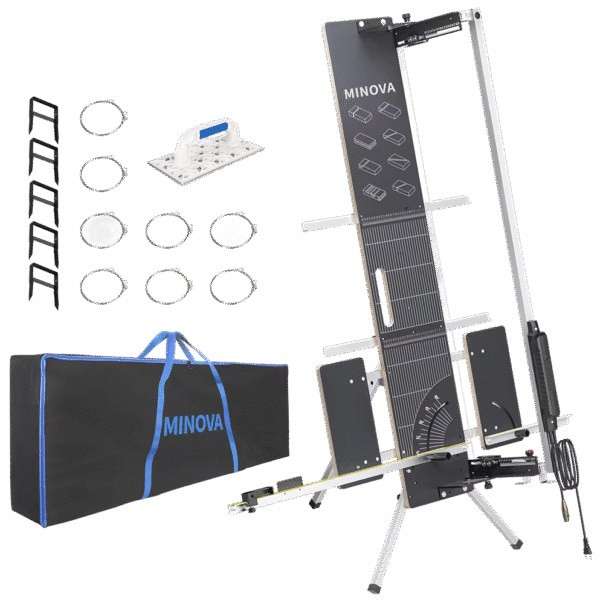

The blade is indispensable in several situations. The first is mobile work - the knife will fit in your tool bag and is ready to use at any time without preparing a stand. The second is shape cutting - you will make arcs, circles, complex figures much easier with a knife than with a wire. Minova knife offers just such versatility of application.

The third situation is on-site finishing work. When fitting insulation boards to reveals, machining edges or cutting holes for installations, the blade knife is second to none. The fourth is artistic and modeling work, where precision and the ability to make very detailed shapes are needed. Wire just doesn't give you that much control over the tool.

Grooves in Styrofoam - when is a blade irreplaceable?

Grooving is a task where the blade completely displaces the wire. A hooked blade guided along a line cuts an even groove of consistent depth without the need for multiple passes. With wire, making a groove requires either a complicated guiding system or repeated grinding, which is time-consuming and less precise. Various techniques processing foam materials use specialized blades.

The depth of the groove is controlled by the angle of the knife and the force of the pressure. Shallow decorative grooves are made with a light touch, deeper construction grooves require stronger guidance. The key is to maintain a constant angle and speed - any change leaves a visible mark. For long grooves, it's a good idea to use a guide or stretched string as a guide line.

Top rated products

How to cut with a flat knife? Practical tips

The basic technique is similar to working with an ordinary knife, but it requires taking into account a few important differences. The heated blade melts the material, so don't apply a lot of pressure - just gentle contact and even guidance. Too much pressure deforms the material, too little makes the blade slide across the surface without cutting. For detailed instructions, see our handbook.

The guiding speed adjusts to the thickness of the material and the temperature of the blade. Thin slabs can be cut quickly, thick ones require a slower pace. Guiding too fast does not give the blade time to melt the material, while guiding too slow results in excessive melting and dabbing. The optimal speed is about 5-10 cm per second for standard polystyrene foam.

Temperature control in blade knives

Temperature control significantly increases the versatility of the tool. Different materials require different temperatures - soft EPS polystyrene melts at a 250-300°C, hard XPS styrodur needs 350-400°C. Too low a temperature causes the blade not to cut through the material smoothly, too high a temperature causes excessive melting and smoke.

Ranking of knives by user reviews

Professionals give the highest marks to models that combine high power with ergonomics and durability. Key parameters are the speed of heating (the best models reach operating temperature in 3-5 seconds), temperature stability during operation and a comfortable, balanced handle. The cooling system also matters - active fan cooling prevents overheating during long hours of work.

Features of the best-rated models:

- Power 200-250W - sufficient for most applications

- Temperature control - minimum 3 power levels

- Interchangeable blades - easy replacement without tools

- Swivel head - working from different angles

- Active cooling - stable operation for long sessions

What it is used for - grooves, beveling, finishing

The applications of the blade knife are extremely wide. Chamfering the edges of insulation boards improves their adhesion and eliminates sharp angles. Cutting holes for electrical boxes, pipes or other installations is a task where the precision of the knife is irreplaceable.

Fitting components on site, especially with unusual wall or ceiling shapes, requires a mobile tool. Equally versatile in applications is guillotine, which works well for other types of work.

In artistic work, the blade knife allows you to create sculptures, architectural details, spatial letters and mock-ups. The ability to freely guide the tool in three dimensions opens up almost limitless creative possibilities. Modelers use thin blades to precisely cut out elements of dioramas and landscape mockups.

Taking care of the blade and working safely

The blade requires regular maintenance. After each work session, it should be cleaned of deposits of molten material that burn into the surface. This is easiest to do while still warm, when the deposits are soft - just wipe the blade with a cloth. Cold, burnt residue is removed by gently sanding with fine sandpaper.

Security working with a hot blade also requires proper storage and transportation of the tool.

FAQ - Frequently Asked Questions About Blade Knife

What kind of thermal knife for finishing work?

For finishing work, a 200-250W cutter with temperature control, a rotating head and a set of interchangeable blades in different shapes is best.

What is the best way to cut Styrofoam - with a blade or a wire?

For straight cuts a wire is better, for fits, finishes and free-form shapes a blade giving full control is definitely better.

What kind of knife for making grooves in styrofoam?

For grooves, the best is a knife with a hooked curved blade that runs along the line without slipping, creating an even groove.

What is best for precision detailing?

For fine details, a thermal knife with thin pin or hook blades is best, offering full control over the movement of the tool.