Professional machines for cutting polystyrene foam - what is worth knowing?

The difference between hobby and professional equipment is not just price, but more importantly durability, performance and capability. Professional styrofoam cutting machines are designed for hours of work, large quantities of material and repeatable precision. If you're wondering whether it's worth investing in Pro-class equipment, or you're not sure what to look for when choosing one - this guide will dispel all your doubts and help you make an informed decision!

What is the difference between a machine for a professional and a regular one?

The main difference is the build quality and durability of the components. Professional units use reinforced frames made of welded steel or aluminum, which do not deform under hours of use. Power supplies have greater power reserves and do not overheat during intensive use. Wire tensioning systems are precise and easy to adjust, and the design itself provides for the replacement of worn parts without having to buy the entire unit.

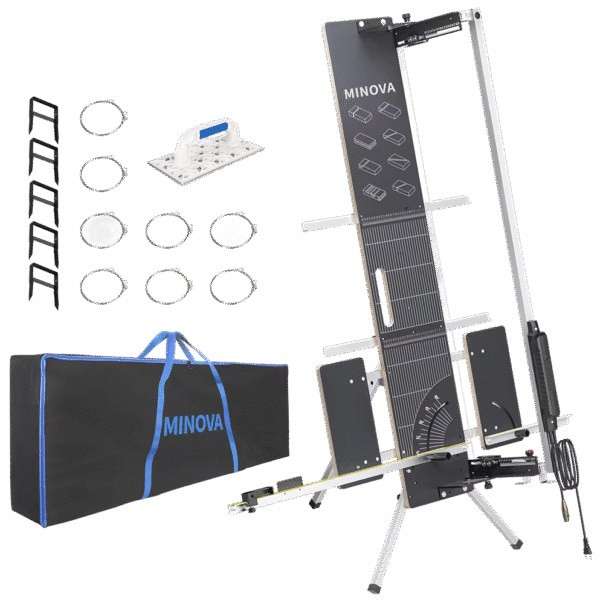

Machines Pro-Cut is an example of an approach where every element has been carefully considered from a professional perspective. Minova ELITE professional cutting machine represents the highest level of sophistication - high-precision guides, a powerful power supply with temperature control and a quick wire change system without tools.

Zalety profesjonalnych maszyn do cięcia styropianu

Investment in professional equipment brings tangible benefits after just a few months of use. Repeatability of cuts is the first - the ability to make a series of identical parts without having to draw lines each time saves hours of work. Speed of cutting while maintaining quality is the second advantage - powerful power supplies heat up the wire in 3-5 seconds, while amateur models take up to 15 seconds.

Key advantages of professional equipment:

- Durability of construction - welded frames can withstand years of heavy use

- Performance - Fast heating and stable parameters throughout the work session

- Precision - Guidance systems eliminate deflection and ensure straight cuts

- Versatility - handling different thicknesses and types of materials with one machine

- Low operating costs - Less frequent breakdowns and easy replacement of spare parts

Types of machines - from simple to advanced CNC

The market offers a wide range of cutters tailored to different needs and budgets. The simplest models are basic tables with wire stretched between two points - these require manual guidance of the material and give limited repeatability. The mid-range are guillotines with guide systems and adjustable cutting angles, ideal for workshops and small businesses. The top tier are computer-controlled CNC systems that automatically cut complex shapes according to programmed patterns.

Guillotines, cutting tables and automatic systems

Guillotines are the most popular choice in professional workshops. They allow fast straight and angled cuts with high repeatability. Cutting tables give more freedom - the material is stationary and the wire moves along predetermined tracks, which works well for unusual shapes. CNC automatic systems are the solution for industrial production, where maximum efficiency and minimization of waste are important.

The choice of machine type depends on the nature of the work:

- Guillotines - Ideal for straight and angled cuts in the construction industry

- Cutting tables - prove themselves in the production of inscriptions and advertising forms

- CNC systems - essential for complex shapes and large-scale production

- Handheld devices - supplement to matching and mobile work

Top rated products

-

Adapter Minova → Makita 18V

Original price was: zł 119.00.zł 99.00Current price is: zł 99.00.

What parameters are really important when choosing?

When choosing a professional machine, three parameters are key: power supply power, maximum cutting length and height, and temperature control range. Power determines how thick materials can be cut and how fast. Cutting length determines the maximum dimension of the workpiece. Temperature control allows you to adjust the parameters for different materials and densities. Machine test shows how these parameters affect the practical capabilities of the devices.

Additional features worth noting are The power supply cooling system, the quality of the guides, the availability of spare parts and the ergonomics of operation. A machine that requires constant breaks to cool down will not perform well in intensive work. Slides with backlash make precise cuts impossible. Lack of access to spare parts means downtime when malfunctions occur. Inconvenient operation leads to errors and operator fatigue.

Best 2025 models - what do professionals recommend?

Among professionals, the most frequently mentioned model is Minova 260W cutting machine, which combines high power with precise design. The 8 cutting types are sufficient for most applications, and the powerful power supply can handle even thick styrodur boards. The tool-free wire change system speeds up maintenance, and the temperature control allows you to work with a variety of materials.

Power, length of cut, temperature - what is important?

The power supply should be a minimum of 200W for professional applications, although 260W gives much more comfort and versatility. Cutting lengths of 100-130 cm support standard building boards, longer models of 150-200 cm are needed for industrial production. The adjustable temperature of 250-400°C allows cutting both lightweight EPS polystyrene and hard XPS polystyrene.

Additional parameters that matter are wire heating time, the thickness of the material being handled and the precision of the guides. Professional devices heat up in 3-5 seconds, handle materials up to 50 cm thick and have guides with accuracy to single millimeters. These parameters directly translate into productivity and quality of work.

Styrodur machine - when do you need more power?

Styrodur XPS is a compact material with a higher density than EPS polystyrene. It requires higher temperatures and more power for effective cutting. While Procut Base cutter with a power of 200W can cope with Styrofoam up to 30 cm, with styrodur it can have difficulties already at 20 cm. Therefore, for regular work with styrodur, we recommend models of at least 260W.

More power means not only the ability to cut thicker materials, but also faster operation and less wear and tear on the equipment. A weaker power supply operates at the limit of its capabilities, which shortens its life. A more powerful model has power reserves and operates at a comfortable level, which translates into years of trouble-free operation.

For whom, what machine - construction, advertising, industry

Different industries have different requirements for equipment. The construction industry primarily needs speed and the ability to cut thick boards - guillotines with powerful power supplies work well. The advertising industry requires precision and the ability to cut letters and logos - cutting tables with the option of shape cuts are the best. The industry relies on automation and efficiency - CNC systems minimize operator involvement.

For more on applications in various industries, see our guide.

Power systems and wire - what's inside?

The heart of any professional cutting machine is a stable power supply and a suitable resistance wire. The power supply converts the current from the socket to the optimal parameters for heating the wire. Professional models have electronic power regulation, thermal protection and voltage stabilization systems. Wire made of alloy NiCr80/20 Maintains stable properties for hundreds of hours of operation.

The quality of these components determines the reliability of the whole device. A cheap power supply can have nominally high power, but under load the parameters drop. Low-quality wire wears out quickly and breaks at the least expected moments. Investing in original manufacturer parts saves time and nerves in the long run.

How much does it cost and is it worth spending more?

Professional machines cost from several to several thousand zlotys, depending on sophistication and capabilities. Basic models for small workshops start at 2-3 thousand zlotys. Advanced guillotines with full adjustment are an expense of 5-8 thousand. CNC systems for industry exceed 20 thousand zlotys. Our store includes full price listings for all available models.

The difference in price is not only better components, but most importantly, service life and operating costs. Cheap equipment after a year of intensive operation requires replacement of key components or fails completely. Professional equipment serves 5-10 years with minimal maintenance costs. If you convert this to working hours, the investment in better equipment pays for itself many times over.

Portable or stationary - which to choose for a company?

The decision depends on the organization of work and the nature of the projects carried out. Detailed comparison will help select the optimal solution. Construction companies working on various sites often choose a combination - a stationary cutting machine in the warehouse for preparing standard parts plus thermal cutters for on-site adjustments.

Production workshops and advertising companies rely on stationary workstations with full equipment. This gives maximum efficiency and repeatability, which is crucial for mass production. Mobility is not a priority when all work is done in one place. Investing in a solid stationary workstation is the foundation for efficient production.

Technical support and machine service (we do it!)

One of the key criteria for choosing professional equipment is the availability of technical support and service. We provide comprehensive support for all equipment - from assistance in selecting the right model, to training in operation, to warranty and post-warranty repairs. Access to original spare parts and fast service response times are what distinguish professional service from basic service.

For more information, visit about the company.

FAQ – Najczęściej zadawane pytania o profesjonalne maszyny do cięcia styropianu

What is the best cutting machine for a small construction company?

For a small construction company, a 200-260W guillotine with a cutting length of 100-130 cm is best, providing performance and versatility at a reasonable price.

How much will I pay for a decent industrial machine?

A decent industrial machine is an expense of 5 to 15 thousand zlotys, depending on the capabilities, CNC systems for large production exceed 20 thousand zlotys.

What is the best for large-scale Styrofoam cutting?

For large-scale cutting, stationary guillotines or cutting tables with powerful power supplies and guidance systems for repeatability and efficiency are best.

What tool to buy for professional work?

For professional work, it is advisable to buy a stationary cutting machine of at least 260W with temperature control and guide system plus a portable thermal knife for fitting.